Hazardous Area Electrical – Classification, Design & Installation

DaD Electrical helps sites identify and manage hazardous areas, providing classification, design, installation and inspections aligned with explosive-atmosphere requirements and AS/NZS 60079 concepts.

- Area classification & zone drawings

- Equipment selection & installation

- Existing sites, upgrades & new builds

Sites Where Hazardous Area Design Matters

Hazardous areas show up in more places than just fuel depots. We support a range of sites where flammable gases, vapours or dusts need to be managed properly with suitable electrical design.

Fuel, LPG & Truck Loading

Fuel dispensers, LPG storage, tanker bays and truck loading areas where vapours and spills need to be considered in the electrical design.

Industrial & Process Plants

Pump rooms, mixing areas, solvent handling, spray booths and process lines in industrial environments.

Food, Agri & Rural Sites

Grain and feed handling, dairy sites, silo areas and other dust or vapour-prone locations on farms and processing plants.

What We Do in Hazardous Areas

We help identify where explosive atmospheres may occur, document the zones and provide electrical solutions that fit the classification – from equipment selection to inspection and tidy-up of existing work.

Area Classification & Zone Drawings

Identify where explosive atmospheres may exist and how that affects the electrical installation.

- Review of processes, products and release points

- Development or update of zone maps and sketches

- Identification of hazardous and non-hazardous boundaries

- Recommendations for cabling, equipment and protection

- Documentation to support future maintenance and audits

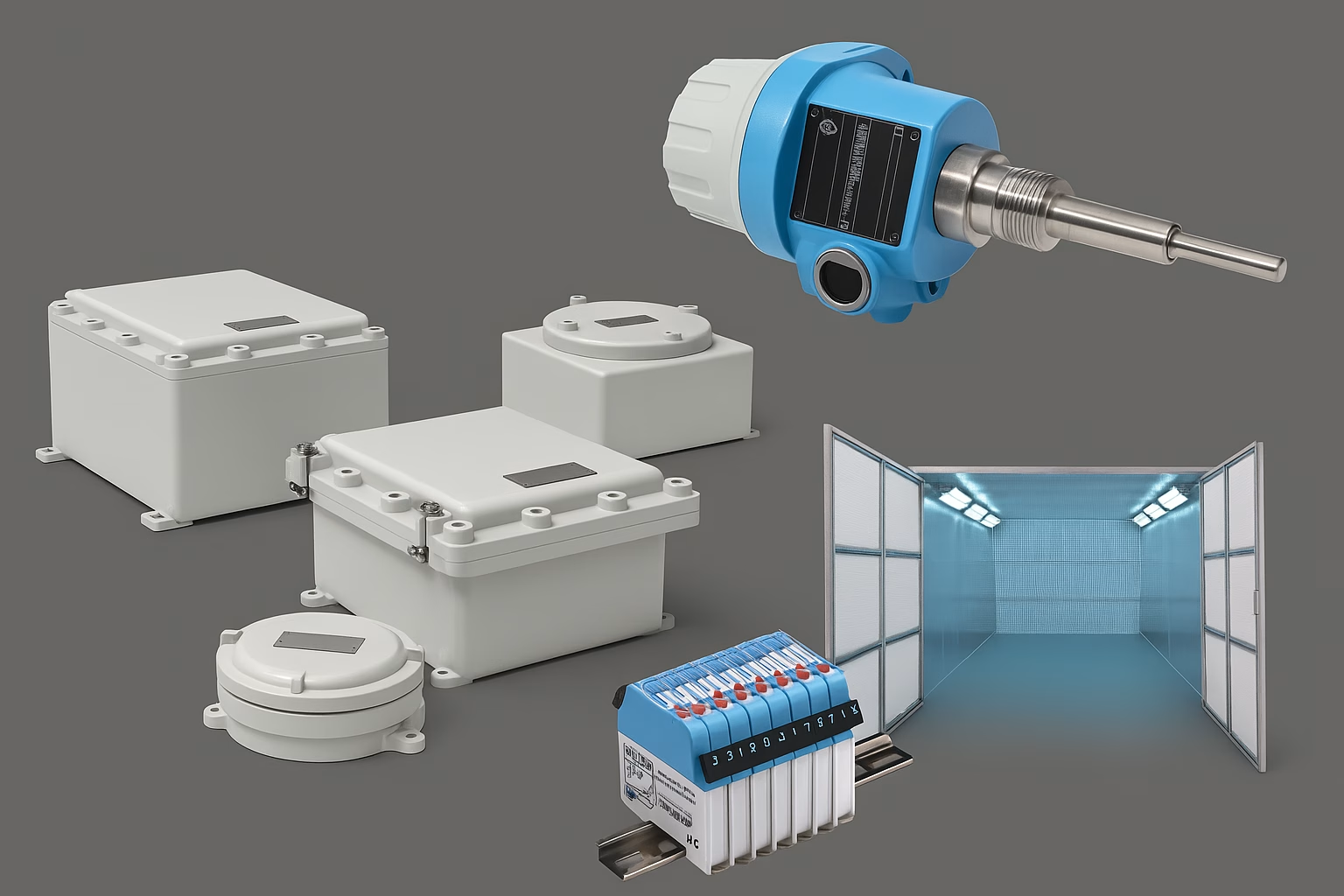

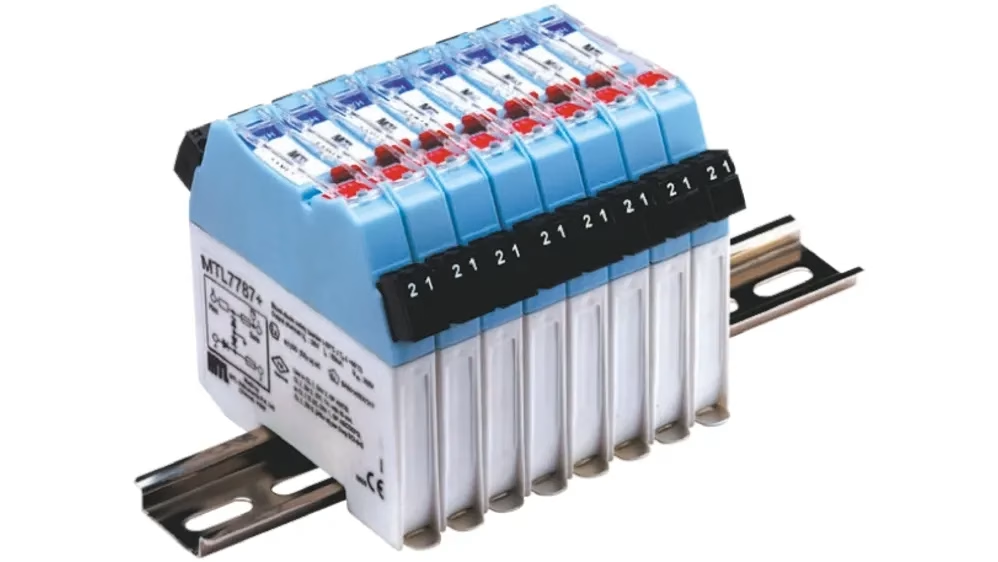

Equipment Selection & Design

Choosing and designing with suitable Ex equipment and wiring methods for your zones and site type.

- Selection of Ex-rated luminaires, junction boxes and accessories

- Wiring systems, cable types and glanding suitable for the zone

- Segregation between hazardous and non-hazardous circuits

- Labelling and identification of hazardous area equipment

- Consideration of maintenance access and future changes

Installation, Inspection & Remediation

Installing new work correctly and identifying issues in existing hazardous area installations.

- Installation of Ex equipment, cabling and glands

- Inspection of existing hazardous area circuits and terminations

- Identifying non-compliant equipment or wiring practices

- Remedial works to tidy, label and improve existing installations

- Ongoing support as processes and equipment evolve over time

Different Hazardous Environments, Different Approaches

The same standard applies across many industries, but each site type has its own patterns of releases, cleaning and maintenance. We adapt the design to match how your site actually works.

Fuel, LPG & Truck Loading Areas

Fuel and tanker areas tend to have obvious risks, but the details still matter – from dispensers and fill points to pits, ducts and trenches where vapours can collect.

- Classification around dispensers, fill points and vents

- Consideration of grades, pits and low points where vapours settle

- Lighting, switches and junction boxes placed outside zones where practical

- Routing of cabling to avoid unnecessary entry into hazardous volumes

Industrial, Pump Rooms & Process Areas

In industrial spaces, hazardous areas might only exist around specific pieces of equipment. We focus on separating normal plant wiring from the hazardous zones wherever we can.

- Classification of pump rooms, mixing areas and vented equipment

- Grouping and routing of cabling to keep terminations accessible and visible

- Use of appropriate enclosures and cable entries in the hazardous volume

- Support when new solvents, products or processes are introduced

Dusty, Food & Rural Environments

Grain, feed, powders and other combustible dusts can create hazardous conditions around conveyors, bins and process equipment. We consider how dust is generated, cleaned and collected.

- Identification of dust zones around conveyors, bins and hoppers

- Selection of equipment suitable for dusty or washdown environments

- Cable and gland choices that tolerate cleaning and movement

- Support as plant changes or expansions alter the risk profile

Structured Approach to Hazardous Area Work

We treat hazardous area electrical as a structured process – understand the risk, classify, design, then install and inspect.

Site Information & Review

We gather information on products, processes, release points and existing electrical work, backed up by photos, drawings or a site visit.

Classification & Concept Design

We determine where hazardous zones are expected and outline how that affects equipment selection, wiring routes and segregation from non-hazardous areas.

Installation / Remediation

Electrical work is installed or corrected in line with the classification – with attention to cabling, glands, terminations and equipment placement.

Inspection, Labelling & Support

We check critical items, label equipment and provide information to support future inspections, maintenance and changes on site.

Hazardous Area Electrical – Common Questions

If you suspect part of your site might be hazardous – or an auditor has asked questions – it’s better to get clarity early.

Even relatively small areas (a pump room, fuel bay or silo) can have hazardous zones that need to be recognised in the electrical design. We’re happy to look at photos, plans or process descriptions and give initial guidance.

From there we can move into more formal classification, design and remediation work as needed for your site.

How do I know if I have a hazardous area? +

Can existing electrical work be made compliant? +

Do I need full drawings to start? +

What information helps with quoting? +

Discuss a hazardous area project

Tell us about your site, what materials or processes you have, and share any photos or plans you can. We’ll respond with recommended steps and indicative pricing ranges.

Need clarity on hazardous areas at your site?

Call or email DaD Electrical and we’ll walk through what you’re working with – whether it’s a single fuel bay or a more complex industrial or rural installation.